![]()

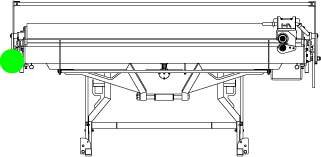

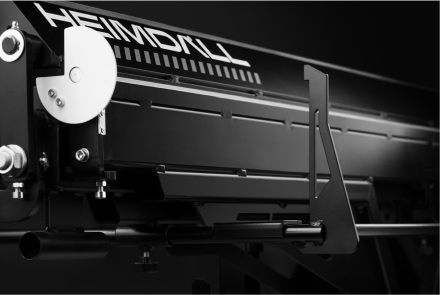

LIGHT MANUAL BENDING MACHINE M-BL1

![]()

VIDEO PRESENTATION

![]()

WHO IS IT FOR?

LYNX™ is a bending machine for those who approach their work individually and want to do it alone. They expect solutions that ensure the comfortable operation of the machine. A model designed for independent work andreducing costs. In contrast to the bending machine, URSUS has handles for carrying as well as fastening brackets for transport belts.

![]()

SPECIFICATION

| working field | 2190 mm |

| length | 2430 mm |

| width | 800 mm |

| height | 1210 mm |

| weight | 165 kg |

| bending angle | 140° |

| clearance | 60 mm |

| bending element | 15 mm |

![]()

MAXIMUM BENDING THICKNESSES

| steel | 0.8 mm |

| aluminum | 1 mm |

| rostfrei | 0.5 mm |

| stainless | 1 mm |

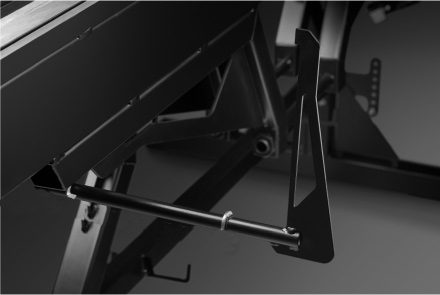

LIGHTWEIGHT MANUAL BENDING MACHINE M–BL1

Efficient self-lubrication system ensures a high machine life, low coefficient of friction and maximum damping of vibrations.

![]()

(A)

bending

![]()

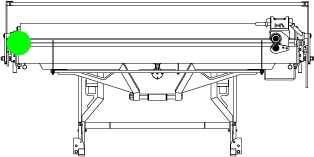

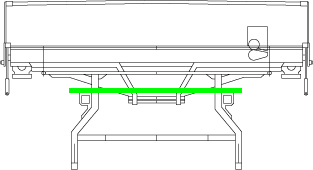

(01)

OPENING AND CLOSING HANDLE

...upper beam. It is thanks to thisthat it is possible to operate the machine for a single person – and anywhere.

![]()

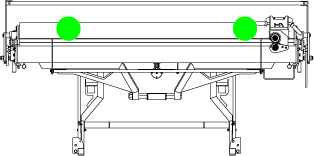

(02)

Holding magnets

They stabilise the sheets during measuring, thereby enabling independent work. They are very durable (neodymium). They are placed below the guide surface of the sheet – they do not touch it.

![]()

(03)

PROTRACTOR

It allows you to monitor the bending angle of the sheet. It is precise and placed in a clearly visible place. It shows great resistance to external conditions and abrasion.

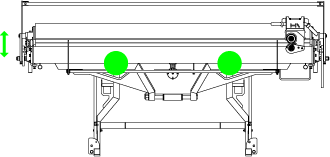

(04)

HEIGHT ADJUSTMENT

Helps to create a comfortable workplace – the height of the machine can be adapted to the needs of the operator (adjustable up to 12 cm).

(05)

REAR TABLE WITH GRADUATION

Large (up to 10 sheets), stable, easy to assemble and disassemble. Equipped with wooden slats to ensure the safety of the material as well as bumpers with graduations allowing for serial cutting and bending.

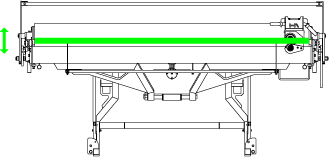

(06)

PRESSURE ADJUSTMENT SYSTEM

It gives the possibility of adjusting the clamping force to the thickness of the compressed sheet.

![]()

(B)

cutting

![]()

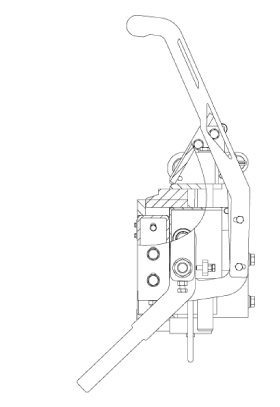

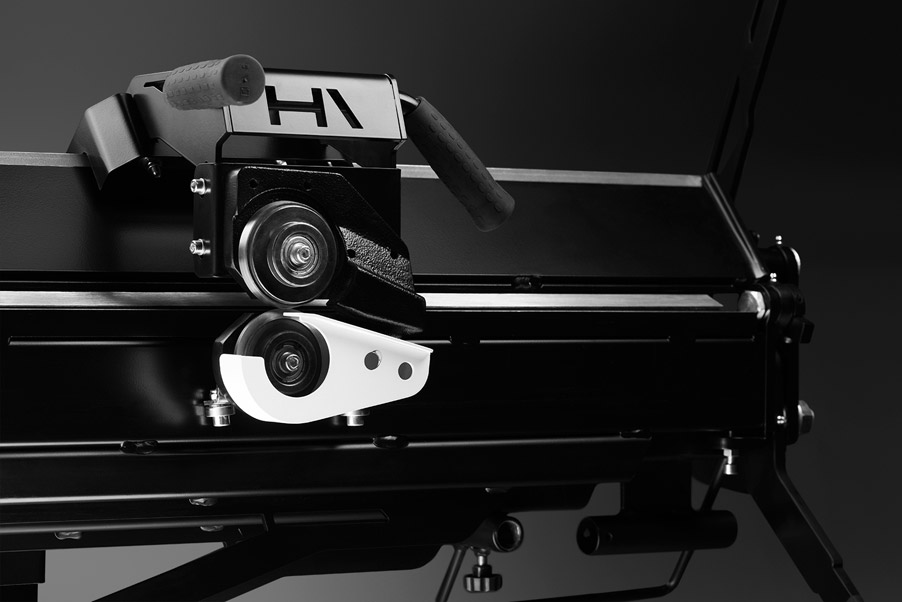

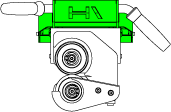

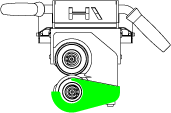

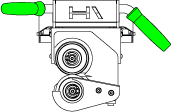

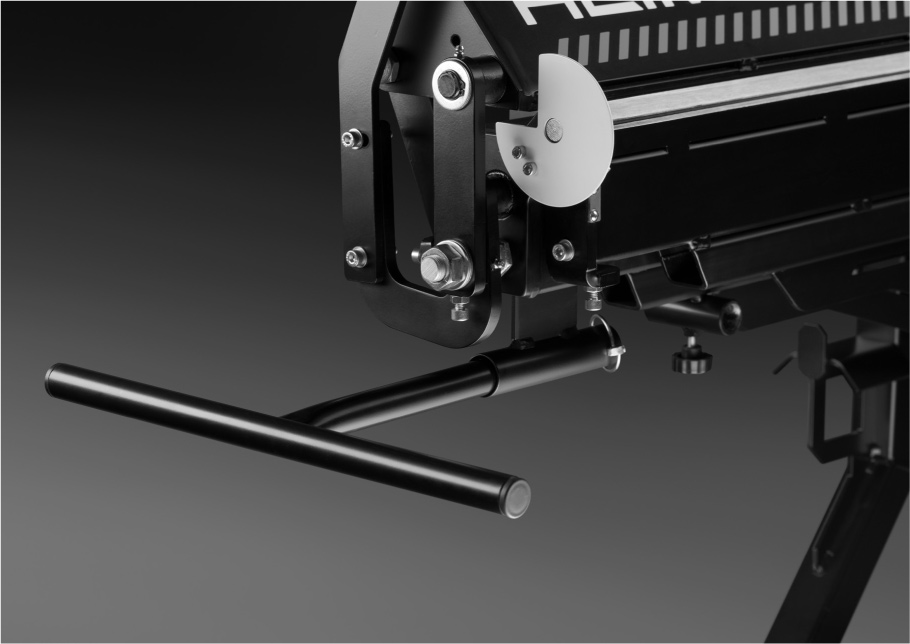

(01)

CIRCULAR KNIFE

Equipped with a lower disc cover, thanks to which the disc does not chip and the sheet metal does not get dirty. Durable metal bearings with a double-sided lock prevent the knife from falling out. Its handles are protected by a rubber cover.

![]()

(01-A)

BEARING HOUSING

(01-B)

LOWER DISC COVER

(01-C)

ERGONOMIC KNIFE HANDLE

(01-D)

DISTANCE OF THE KNIFE FROM MACHINE

![]()

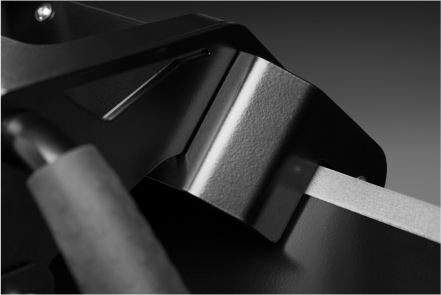

(02)

PLACE TO STORE THE KNIFE

It prevents excessive wear of the bearings and cutting wheels (the cutting knife does not come into contact with the sand). It facilitates the work of the operator who can have a knife always at hand.

(03)

FRONT BUMPERS

Their design ensures that the cutting width of the sheet is kept constant and allows for the flexibility of its movements (there is no risk of corrugation).

(04)

DROP RAIL

This prevents the detached sheet strips from falling onto the platform and it protects the operator’s legs.

![]()

(C)

transport

![]()

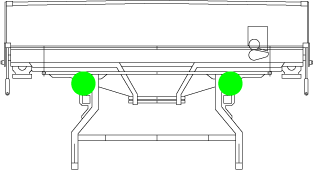

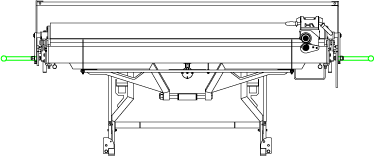

(01)

MOUNTING BRACKETS

...for transport belts. Provide the machine with safe and stable transport by vehicle. Designed from the ground up to protect its calibration and precision.

(02)

CARRYING HANDLES

They enable safe and trouble-free handling of the machine in the workplace. They can be dismantled.

(D)

accessories

![]()

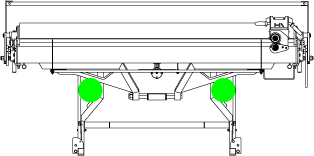

(01)

WHEELS

Large (220 mm/60 mm), noninflatable and yielding, thus durable. They enable fast and safe movement of the bending machine, even indifficult terrain. You can bend them.

![]()

(02)

QUADRUPLE LIMITER

It is a guarantee of stability and precision. Thanks to it, you can set four selected, repeatable bending angles.

![]()

(03)

FRONT BUMPERS TAPELINE

They eliminate the differences in dimensions between the knife and the machine, showing the real, exact size of the cut..

![]()